There are numerous jobs that a person can do nowadays, but physical work is still very popular, although many aspects of it are being modernized as each year goes by. Glass-lifting robots are very popular in the construction industry, and they play a huge role when it comes to safety, precision, and completion of tasks that require a lot of attention.

Today we are going to talk about these so-called glazing robots, so if you are interested in learning some more about what they are, the way they work, or you are in the process of purchasing one, feel free to stick around until the end, and we’ll help you make a better decision. Here’s what you need to know.

Why the need for glazing robots?

If the construction industry was working perfectly all these years without the glazing robots, why the sudden need for human replacement? Well, here’s the thing. Although humans are perfectly able to place a huge glass panel, resource and safety-wise it’s not the most optimal way to do it.

One glass panel, especially the huge ones used for buildings, can cost up to a thousand dollars, and we all know how fragile glass is. You don’t even have to end up breaking it, a few scratches on it and it is already unacceptable by the person who owns the place.

Besides, you should not underestimate the weight of these things, because a panel can weigh up to a hundred kilograms, or even more, depending on the size and the thickness of it. All of these factors combined can increase the risk for something bad to happen at the site, and a robot is pretty resilient to weight and the rest of the factors.

It’s easy to operate

Although it might sound complicated to operate a robot that needs to perform such a delicate task like placing a fragile glass panel in the right place, it isn’t, and it can be learned in less than a week. The commands are pretty straight forward, and some of them even operate by themselves, but we are talking about very advanced models that might not be available at your site.

There are many different models of these instruments that come with different command panels and controls, so if you worked with one type previously, and now you need to operate with a completely different brand, things might be slightly different, but that doesn’t mean that you won’t learn it fast.

They don’t cost a lot of money

When we say that glass-lifting robots don’t cost a lot of money, we don’t mean that everybody can own one, but compared to the price that you have to pay for the five people who need to do the same task as one robot, they are pretty affordable and well worth it.

Besides, if humans end up making an error, and the glass somehow gets damaged, or completely shattered, you will end up paying a lot more for the panel. Imagine if this happens multiple times, which is quite possible in the career of a construction worker. If you are interested in seeing the best and latest models, you can visit Central Platform Services. The estimated ROI period for them is about a year, so expect to get your investment back real quick and from there it’s just profit.

Injury Prevention

Things aren’t always about the money, and this means that you should be paying attention to other factors such as safety. When a huge panel ends up breaking, the people around it can get injured. When someone gets injured during work, you as the business-owner have to pay a certain price to cover all the expenses. Besides, if it wasn’t the fault of the workers, you can even end up being sued, which is something that you don’t want if you wish to keep your reputation on the highest possible level.

With the glass-lifting robots, you will be able to completely reduce the chance of an injury because of the distance that is kept between the panels that are being placed and the nearby workers. Even if something goes wrong and the glass gets detached from the suction cups and ends up breaking on the ground, the shards flying around won’t hit anyone.

They are very functional

We already mentioned that for the average worker, the weight of the panel might be more than enough to handle, which is something that directly impacts the safety risk percentage. Although these robots are pretty small in size, you shouldn’t underestimate their ability to carry weight.

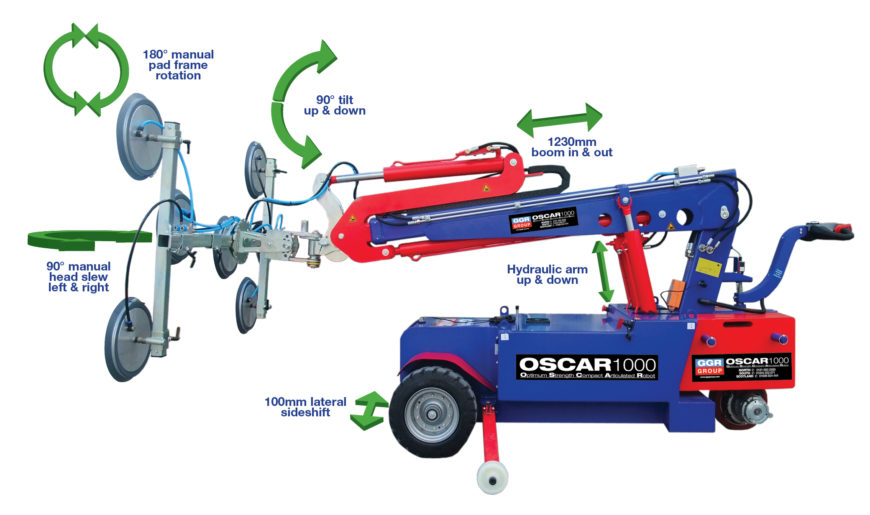

The metal “arms” and the engines producing all of the power are pretty strong, and they can lift panels that weigh over a few hundred kilograms with ease. The really interesting part is that they use specially-designed suction cups that stick on the panel allowing for a safe lift and maneuver without any chances of causing damage to the glass.

Time is money

Every business owner knows that the faster they get a certain job done, the better it is for profit. Well, that’s pretty much the biggest reason why robots are completely replacing humans in modern industries because they operate a lot faster and they never get tired.

Commercial glaziers are known for the ability to cut the time required for the completion of the task by three or four times, meaning that if it takes four days for your workers to cover an entire building, it can be done in just one day thanks to technology.

They can reach where humans can’t

Not everybody is tall, and even if they are, humans certainly don’t reach a height of over five meters. Well, although that’s fine, it doesn’t neglect the fact that some shops and buildings require glass being placed on the exact height of five meters. Humans cannot reach these places, or they can by using ladders, but that’s not very smart when you are carrying over a hundred kilograms of fragile glass in your hands.

Robots, however, they don’t care about the difficulty of the task, and most of the commercial models can reach five meters without any issues, once again proving their superiority over regular workers.